One of Port Hope’s most familiar and friendly faces is about to become a little less familiar. Walton Street stalwart and founder of Kingsmill Kitchens, Gary Potter, is set to retire. When one is fully consumed by establishing a new business, succession planning as it has become known, is the last thing on one’s mind. But time marches on relentlessly, life happens, and soon grey haired experience is to be replaced with youthful exuberance, but more of that later.

Kingsmill Kitchens was established in Toronto in 2001, taking its name from the area in which the business was located, known as the Kingsway in the West End and the proximity to an historic mill. Years later, walking round the area Gary discovered a road called Kingsmill Street, and realized that the name he had chosen was not quite as original as he had imagined. Working on his own for many years, Gary successfully built up the business to the point where he began to realize it could not continue to grow without more hands on deck. Gary partnered with his old friend, Tony Hunt whom he had known for many years after meeting him at a conference of the National Kitchen & Bath Association. Apart from needing the extra manpower, Gary wanted someone off whom to bounce ideas. Since the pair of them began working together they have won at least thirty-two awards for the quality of their kitchen design.

Sometime later, on a relaxing weekend drive out of Toronto, Gary found himself in Port Hope where he noticed a vacant store which had previously been an antique shop. He started to ponder about opening a second branch of Kingsmill Kitchens. As fate would have it, the landlord had an office not too far from Gary’s location, following a few phone calls, the deal was signed on the line: Kingsmill Kitchens had another outlet. Initially this worked out quite well, Gary concentrated his attention on establishing the Port Hope venture, leaving Tony to manage the Toronto operation, which was quite convenient for him as he lived in Newcastle. As the business prospered, it became increasingly challenging to manage, consequently Gary and Tony decided to cover Toronto from the Port Hope location and operate exclusively from there.

Gary attended the Ontario College of Art studying interior and industrial design, graduating in 1975. As a very bright student, he was recruited by a Markham based company, Destron Incorporated, as a senior designer no less. They sent him to Hong Kong to oversee the manufacture of electronic products. A now defunct magazine, Select Homes was responsible for Gary’s next career choice: he read about certified kitchen designer courses run by the National Kitchen and Bath Association and it peeked his interest. Gary was interviewed and offered a position at the Hanover Kitchen and Bath Gallery in North York. A few days later he attended the Hanover plant for training, after which he succeeded in selling a kitchen design in his first month in the position. He reflects, “My dad was a cabinet maker, so perhaps it was inevitable.”

Going forward the Kingsmill Kitchen’s team will be headed up by Tony Hunt whose twenty-four years of experience should keep things running smoothly with the assistance of Isabella Chamorro, a graduate of Georgian College, and previously the University of Santo Thomas, Manila. Daily activities are coordinated by Showroom Manager, Megan Hunt, whose has a background in hotel and restaurant management.

Gary observes, “Kitchen design has changed quite a bit over the years, when I started out designs were drawn out with a pencil and a ruler, now everything is computerized.” His philosophy on kitchen design has been to try and find some aspect of the space which provides a unique opportunity to work with the space rather than impose an off the shelf solution. In an historic home, this might mean incorporating existing design elements in a novel way. Gary recommends we avoid fast fashion and stick with classic timeless designs. “Remember avocado bathroom suites,” he muses, “everyone thought they were very chic, but that opinion didn’t last.”

I asked Tony what’s the next big thing in kitchen design, and the answer is “steam ovens which are one of professional chefs’ best kept secrets.” Using steam increases flavour and eliminates dryness. This technique hasn’t yet quite caught on in the west, but it is very popular in Chinese and East Asian cuisine, where bamboo steamers have been used for many years. Tony says, “What was old is new again.”

If you are thinking about renovating your kitchen, this would be the time to explore cooking with steam. There are very few tasks that a combination steam-convection oven cannot accomplish, apart from heating up your cold coffee. Tony insists, “coffee should always be fresh.” It will cook your food all the way through, even from frozen, rarely requires oil or seasoning, and retains moisture and nutrients, leaving your food tastier and healthier.

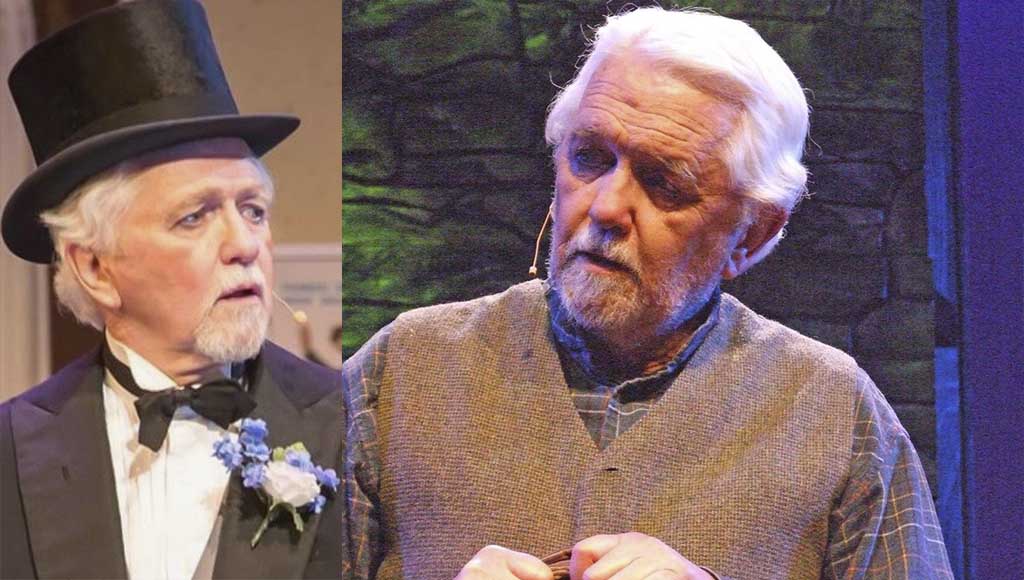

For the future Gary proposes to spend more time performing in community theatre, perfecting his water colour painting technique and reading a good book with a glass of wine.

Originally kitchens were a small room with little more than some form of cooking appliance and a sink with a random assortment of furniture as working space: how things have changed. Now the kitchen has become the heart of the home, a social space, indeed almost a second lounge. Ideas about what a kitchen should be like developed through the 1920s, and have evolved following technological innovations, such as fridge-freezers and dish washers, and the availability of new materials. Quieter and smaller appliances allowed space for dining nooks to sneak into the kitchen, where they took root. The dining room incorporated itself into the kitchen, perhaps no longer as a dining table, but as part of an island. It is believed that the origin of the expression “happy wife, happy life,” comes from marketing campaigns for the earliest dishwashers. Also in the twenties, engineer, Lillian Moller Gilbreth, devised the concept of the working triangle which brought ideas about time and motion and efficiency derived from manufacturing into the domestic environment.